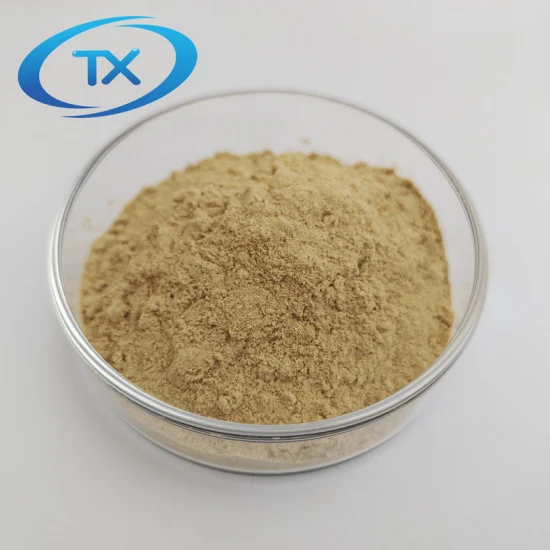

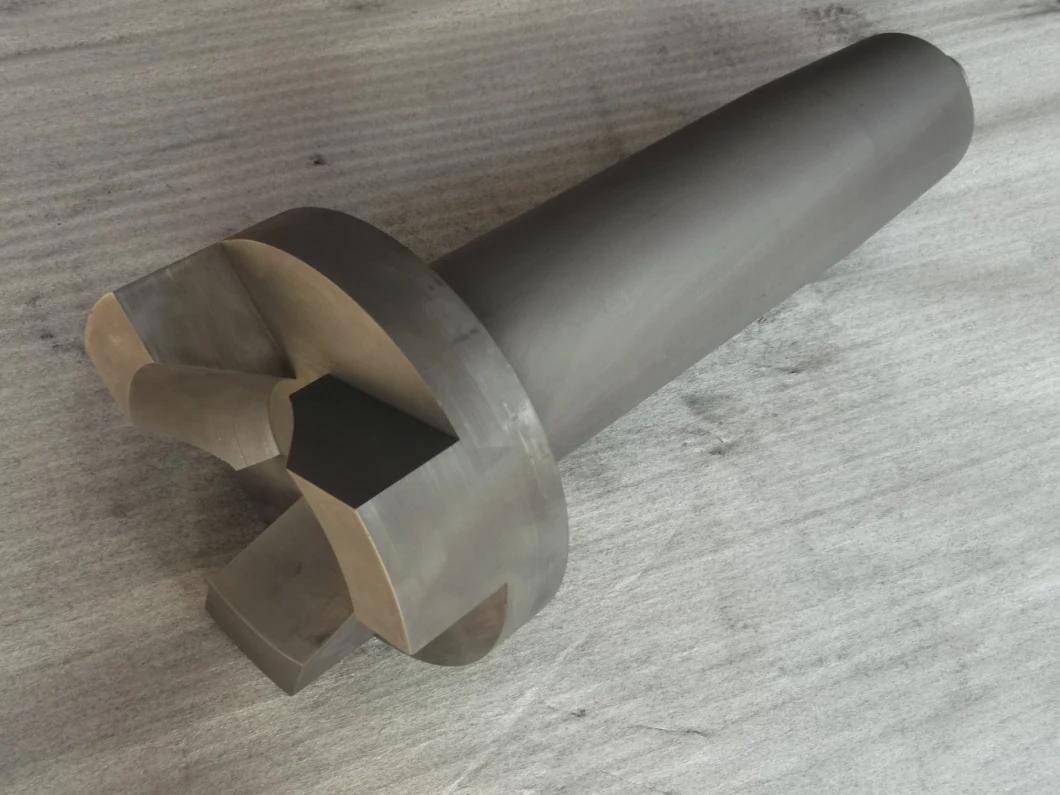

Low Wear/Friction Specialty Graphite Resin Rotors and Vanes for Pumps

Basic Info

| Model NO. | GTL-08-01-072 |

| Bulk Density | 1.71g/cm3-1.85g/cm3 |

| Transport Package | Plywood Cases |

| Specification | Customized |

| Trademark | Gotrays |

| Origin | Shandong, China |

| HS Code | 3801909000 |

| Production Capacity | 30000/Per Month |

Product Description

During aluminum and aluminum alloys smelting, hydrogen is produced by chemical action with steam and diffuses in molten aluminum, which will cause inner structural defect in aluminum products. In order to avoid such defect, most aluminum factories apply dissolved gas floating method to purify molten aluminum. i.e. inert gases such as nitrogen, argon is injected into molten aluminum, and hydrogen will be brought to molten aluminum surface with spread and rise of inert gas. Graphite rotor and shaft set is necessary to inject inert gas and stir for degassing regarding both intermittent and continuous online degassing methods. Thanks to properties of heat-resistance, anti-oxidation, high strength and non- infiltration, graphite becomes the optimal choice for material of rotor and shaft, which is also named as graphite degassing rotors/impllers and shafts.

Type | Average Grain Size (µm) | Bulk Density (g/cc) | Specific Resistivity (μΩ·m) | Flexural Strength (Mpa) | Compressive Strength (Mpa) | Shore Hardness | C.T.E(100-600ºC) ×10-6/ºC | Ash (ppm) |

| GT-CIP5F | 6 | ≥1.8 | ≤13.0 | ≥55.0 | ≥125.0 | ≥70.0 | ≤4.7 | ≤30 |

| GT-CIP5ST | 3 | ≥1.86 | ≤13.0 | ≥68.0 | ≥135.0 | ≥85.0 | ≤6.8 | ≤30 |

| GT-CIP1FR | 15 | ≥1.78 | ≤11.0 | ≥35.0 | ≥70.0 | ≥40.0 | ≤5.5 | ≤30 |

| GT-CIP1FV | 15 | ≥1.85 | ≤15.0 | ≥40.0 | ≥80.0 | ≥46.0 | ≤4.8 | ≤30 |

| GT-CIP1Q | 8 | ≥1.8 | ≤14.0 | ≥50.0 | ≥110.0 | ≥60.0 | ≤5.9 | ≤30 |

| GT-CIPRQ | 8 | ≥1.85 | ≤14.0 | ≥58.0 | ≥130.0 | ≥68.0 | ≤5.9 | ≤30 |

| GT-CIP1RB | 6 | ≥1.89 | ≤14.0 | ≥68.0 | ≥150.0 | ≥70.0 | ≤5.9 | ≤30 |

| GT-CIP4SX | 20 | ≥1.80 | ≤13.0 | ≥45.0 | ≥90.0 | ≥60.0 | ≤4.7 | ≤30 |

| GT-1RV | 10 | ≥1.67 | ≤15.0 | ≥36.0 | ≥78.0 | ≥58.0 | ≤5.8 | ≤30 |

| GT-2C | 15 | ≥1.72 | ≤15.0 | ≥50.0 | ≥100.0 | ≥57.0 | ≤5.8 | ≤30 |

| GT-3S | 12 | ≥1.78 | ≤17.0 | ≥52.0 | ≥102.0 | ≥60.0 | ≤6.0 | ≤30 |

Zibo Gotrays' Focused Applications

- Graphite rotor and shaft will be installed on degassing machine for molten aluminum purification

Our Advantages

Zibo Gotrays' Advantages :

- Specially Impregnation and Coating Anti-oxidation Treatment.

- Customize: Produced according to Customers' Needs.

- Professional Design Ability according to Application.

- Complete Supply Chain System Assuring Competitive Product Price.

- Globally 7x24 Sales and Technical Services, Fast Response for Delivery.

Detailed Photos

Company Profile

Certifications

Packaging & Shipping